What Is LSR Molding and Why It Matters

Liquid Silicone Rubber (LSR) molding is a specialized manufacturing process used to create high-performance silicone rubber parts with extreme accuracy. It involves injecting a two-part liquid silicone compound into a closed mold, where it cures into a solid elastomer. This method is widely used in industries that demand tight tolerances, consistency, and scalable production.

Unlike traditional rubber molding methods, LSR molding delivers repeatable results even in high-volume manufacturing environments, making it a preferred choice for modern silicone rubber injection molding projects.

Understanding Silicone Rubber Injection Molding

Silicone rubber injection molding is the broader category under which LSR molding falls. The process uses automated injection systems to combine, meter, and inject silicone into heated molds. This ensures uniform curing and reduces material waste.

Because the silicone starts in a liquid state, it fills even complex mold geometries with ease. This allows manufacturers to produce intricate designs that would be difficult or impossible using compression or transfer molding.

How the LSR Molding Process Works

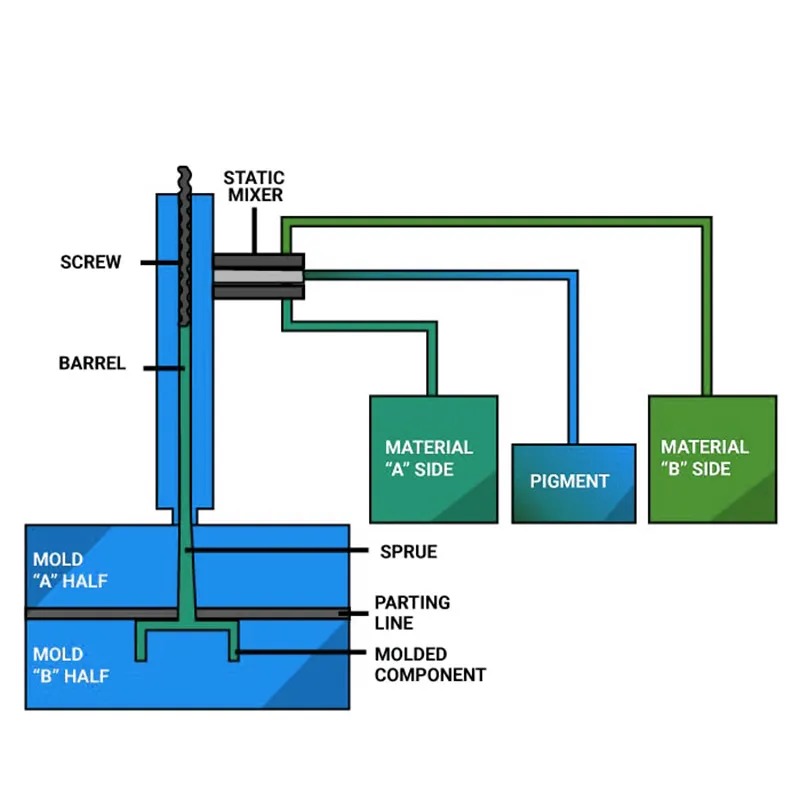

The LSR molding process begins with two liquid components: a base silicone and a catalyst. These are stored separately and mixed in precise ratios before injection. The mixture is then injected into a temperature-controlled mold where curing takes place rapidly.

Automation plays a key role here. Robotic systems manage material flow, injection pressure, and cycle times, ensuring consistency across thousands or even millions of parts.

Key Materials Used in LSR Molding

Liquid silicone rubber is known for its flexibility, thermal stability, and resistance to environmental stress. It maintains its properties across a wide temperature range and performs well in demanding conditions.

Manufacturers can also customize material formulations by adding pigments, fillers, or performance modifiers. This flexibility allows silicone rubber injection molding to meet specific functional and aesthetic requirements.

Advantages of Liquid Silicone Rubber Molding

LSR molding offers several advantages over conventional rubber processing methods. One of the biggest benefits is precision. Tight tolerances can be achieved repeatedly without post-processing.

Other benefits include fast cycle times, minimal material waste, and excellent surface finish. Because the process is highly automated, labor costs are reduced while output quality remains consistent.

Design Freedom with Silicone Rubber Injection Molding

Design flexibility is a major reason engineers choose silicone rubber injection molding. The liquid nature of the material allows it to flow into thin walls, undercuts, and complex shapes.

This opens the door to innovative product designs without compromising performance. Designers can integrate seals, membranes, and flexible features directly into a single molded component.

Applications Across Multiple Industries

LSR molding is widely used in medical, automotive, electronics, consumer goods, and industrial applications. Medical components such as valves, seals, and tubing benefit from silicone’s stability and cleanliness.

In the automotive sector, silicone rubber injection molding is used for gaskets, connectors, and vibration-control parts that must perform reliably under heat and pressure.

Precision and Consistency in High-Volume Production

One of the strongest advantages of LSR molding is its ability to support large-scale production without sacrificing quality. Automated injection systems ensure every part meets the same specifications.

This consistency is critical for manufacturers supplying global markets where product reliability and uniformity directly impact brand reputation and compliance requirements.

Tooling and Mold Design for LSR Molding

Mold design plays a critical role in successful LSR molding. Because the material is injected in liquid form, molds must be designed to prevent flashing while allowing proper venting.

High-quality tooling ensures longer mold life and stable production cycles. Although initial tooling costs may be higher, the long-term efficiency makes silicone rubber injection molding cost-effective over time.

Quality Control in Silicone Rubber Injection Molding

Quality control is integrated into every stage of the LSR molding process. Automated inspection systems monitor part dimensions, surface quality, and curing consistency.

Material traceability and process control help manufacturers meet strict industry standards. This is especially important for applications where performance and reliability cannot be compromised.

Choosing the Right LSR Molding Partner

Selecting the right manufacturer is essential for successful silicone rubber injection molding projects. Experience, technical capability, and process control all influence final product quality.

A reliable LSR molding partner will offer design support, material selection guidance, and scalable production solutions tailored to your needs.

The Future of Liquid Silicone Rubber Molding

As industries continue to demand precision and efficiency, LSR molding is set to play an even larger role in advanced manufacturing. Innovations in automation, tooling, and material science are expanding what’s possible with silicone rubber injection molding.

With its ability to deliver complex parts at scale, LSR molding remains a cornerstone technology for modern silicone product manufacturing.